The AeroDieCut flatbed die cutter offers many advantages for your production. Combine your tried-and-tested steel rule cutting with modern technology.

Your customers need personalised die-cuts faster and in perfect quality. Whether for free-form cards, folding boxes or stickers, the AeroDieCut offers the solution. Easier to use than traditional flatbed die-cutters and more productive than cutting plotters and lasers. The AeroDieCut produces complex cuts, creases and perforations in a single pass.

Punching machines used to be big and heavy and built to last, but they required specialised user knowledge and were fundamentally "dangerous" to use. The AeroDieCut was developed to be operated by virtually anyone, anywhere. The focus is on operator safety and minimising mechanical adjustments.

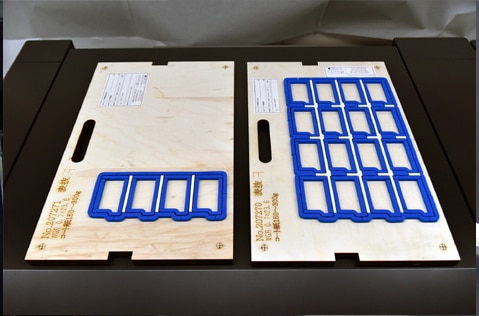

The AeroDieCut uses traditional steel rule cutting tools because they are inexpensive and easy to obtain, while maintaining perfect cutting and creasing quality. The AeroDieCut combines modern technology with the tried and tested.

Your digital printing machines are getting better and better, but even the best print is nothing without the right, modern print finishing.

The possibilities are endless, the AeroDieCut helps you to realise your creativity.

reality and lets your business grow.

Feed unit

The patented "Tri-Suction Feeder" ensures perfect paper feed. Equipped with ultrasonic double sheet control, paper run control, print mark detection to compensate for print fluctuations.

Touchscreen control

The colour 4.3" touchscreen facilitates individual settings. Jobs can be saved.

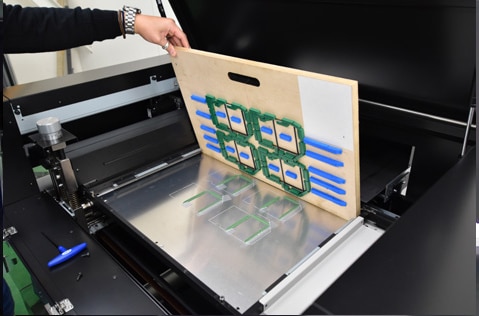

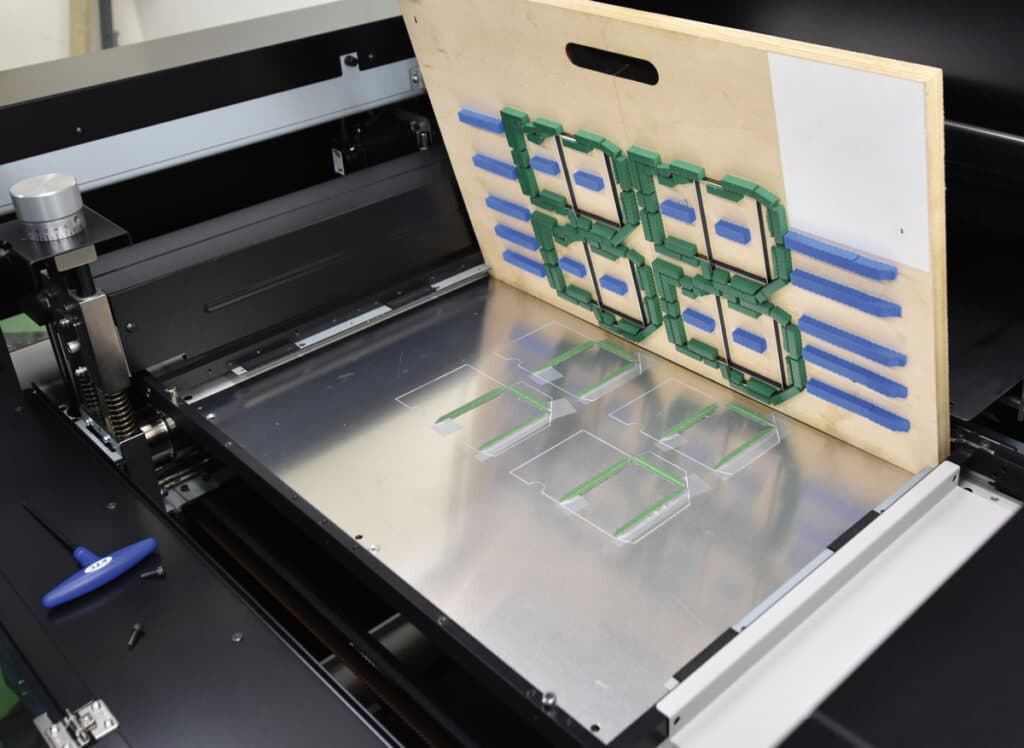

Pressing unit

The press unit uses the patented "Moving Press Rollers" system to punch the paper. The AeroDieCut is significantly quieter and more efficient than conventional punching machines.

Multiple punching

AeroDieCut uses the "step repeat function" for multiple punching with e.g. A4 platen tools (depending on the tool) on A3 sheets.

Optional: Adapter for crucible moulds

Optional delivery and stripping unit

The optional stripping unit separates the blanks from the rest that is deflected into the waste (depending on the cutting die). The optional delivery belt ensures efficient delivery of the blanks.

Versatile applications

The AeroDieCut punches, creases and perforates in a single operation. It transforms your prints into a variety of products such as cards, tags, boxes, envelopes, stickers and much more.

Type: Automatic flatbed die cutter

Processing: Cutting, creasing and perforating at the same time

Max. Paper format: 297 (W) x 420 (L) - 365(W) x 515 (L) mm

Max. Panel format: 310 (W) x 485 (L) mm

Paper thickness: 120 - 400 g, depending on paper

Cutting die format: 350 x 550 mm

Base plate thickness: 18 mm

Tool thickness: 23.3 - 23.8 mm

Operation: 4.3" colour touchscreen

Job memory: 100

Feed type: Suction air "Tri-Suction" (patented) Side blower Diagonal adjustment Side alignment Ultrasonic double sheet control Cut mark detection

Plant capacity: 100 mm

Max. Speed: 1,000 sheets/h

Dimensions: 270 (W) x 107 (D) x 110 (H) cm

Weight: 410 kg

Connection: 240 V, 50/60 Hz

Power consumption: 400 W (230 V)

Options and accessories

Tool rack: Rack for punching tools and counter pressure plates - Incl.

Stripping unit: The stripping unit is hooked onto the delivery. Depending on the layout, it may not be possible to work with the stripping unit - option

Delivery belt: 750 mm long delivery belt. Punched sheets are neatly laid out - option

Counter pressure plate (stainless steel): 3 pcs/set, hard material/long service life/difficult to adjust, for high print runs. For professional users - consumables

Counter pressure plate (aluminium): 3 pcs/set, softer material/shorter service life easy to adjust, smaller runs - consumables

Menu

Menu