With Steuber care we offer you classic services and smart remote maintenance concepts for your printing, finishing and packaging machines.

Ensure the availability of your systems with our all-round support: from repair, via the technical hotline, maintenance, UVV and overhaul of your machines, including spare parts supply, right through to upgrades.

We support you with machine relocations in the company up to the complete relocation of your printing plant with the associated project management.

We are a service and support partner of Koenig & Bauer, MBO, baumannperfecta, Wohlenberg and all manufacturers in our product portfolio in NRW and look after more than 1,800 manroland sheetfed offset printing units in Germany (roof) and Benelux - in terms of service and spare parts supply.

Our hotline is at your disposal

Montag bis Freitag von 7:00 – 17:30 Uhr zur Verfügung.

Phone: +49 (0) 351 / 8 33 - 26 86

Good service is elementary for long-term machine availability. To keep the costs calculable for you, we have developed three individual service packages.

The economy, business and professional modules each offer an annual inspection and a safety check as a basis.

Based on this, you can choose between further services, such as maintenance or free parts delivery.

The basis

The care economy package ensures the functionality and maintenance of your machine.

We give you information about the condition of your machine, inform you about worn parts and small weaknesses that can lead to big problems, all according to the manufacturer's specifications.

In addition, protection and emergency stop functions are checked during the safety check.

After checking all inspection steps, you will receive the inspection report from us and a recommendation of the modules to be overhauled or replaced.

The foundation + maintenance

For high availability, performance and print quality, your press requires professional annual maintenance in accordance with the maintenance plan. Based on this plan, the machine and the aggregates are professionally maintained. The major annual maintenance with adjustment and control of the individual modules / assemblies is only required annually with high machine use in a 3 - 4 - shift operation.

With low and medium machine use, it only occurs every two to three years. In between, minor maintenance is sufficient. It includes checking the most important lubrication points, maintenance of the peripherals, the motors and the fan.

The foundation + maintenance + spare parts

Through inspection, safety check and maintenance, supported by remote maintenance, you have fulfilled important prerequisites to maintain the performance of your machine.

As a care professional customer, you benefit from an extended on-call and diagnostic service.

Free delivery of parts and services, under warranty conditions of the respective manufacturers.

Excluded from this are:

Prerequisite:

The machine is serviced and maintained by the customer in accordance with the maintenance instructions which can be found in the maintenance schedule.

Once a year, the current condition of the machine and the aggregates is determined by qualified service staff. The inspection is carried out according to machine-specific factory inspection lists.

Checking of the safety equipment by qualified service staff as part of the inspection.

Once or twice a year, the machine and the aggregates are professionally maintained on the basis of a factory maintenance plan. The scope of the maintenance work is listed in a separate maintenance plan.

Free delivery of parts and services, under warranty conditions of the respective manufacturers, except for consumables and breakage. Exceptions according to list.

Professional cleaning of your machine according to supplier specifications

Early detection of thermal overloads before they lead to plant shutdown!

Check and control customer-specific settings

Printing inspection of the inking/dampening units in accordance with supplier specifications

Training can be done on site or in our house by arrangement.

24/7 on-call - if available

care MenPower packages work like a voucher card. Book your technician contingent according to your needs and in a calculable way.

Not registered yet?

Contact our service staff

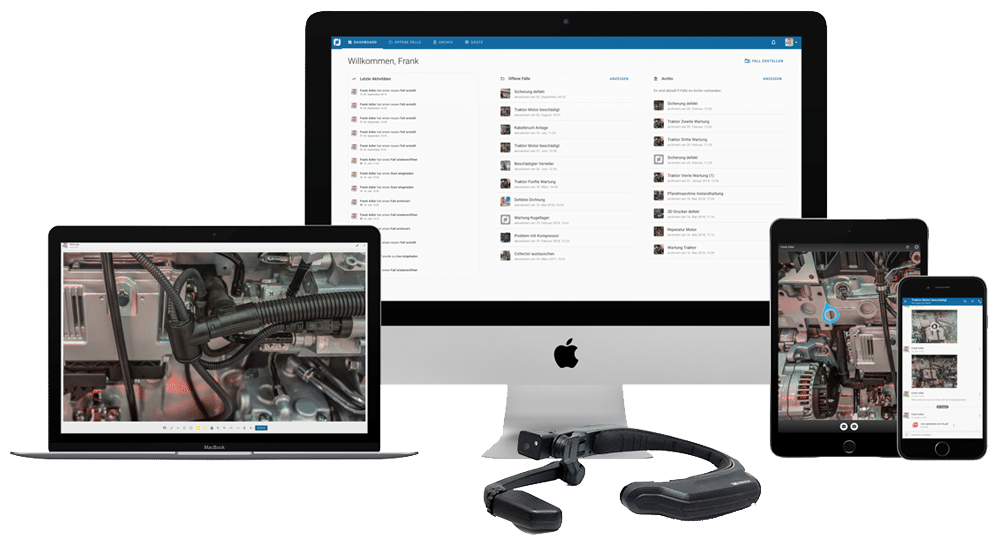

With the latest care package, Steuber care live view Remote Support, you have the option of avoiding on-site technician intervention and minimising downtime.

The heart of the new service offer is the data glasses of our technology partner RISE Technologies.

Customers receive the data glasses for rent from us as well as - of course - full support with the integration of the data glasses into your company network. Once these foundations have been laid, you have already connected to our remote support. Now nothing stands in the way of the first service session, now you are "our eye".

Remote diagnosis via data glasses enables the operating personnel, in cooperation with the Steuber team, to analyse electrical or mechanical problems and initiate the necessary measures - all without the need for on-site technicians.

Regardless of whether printing, print finishing or packaging machines are involved - the service via care live view is not specifically tied to a manufacturer.

Contact us, our service team will answer all your questions about remote maintenance.

Contact now

Menu

Menu