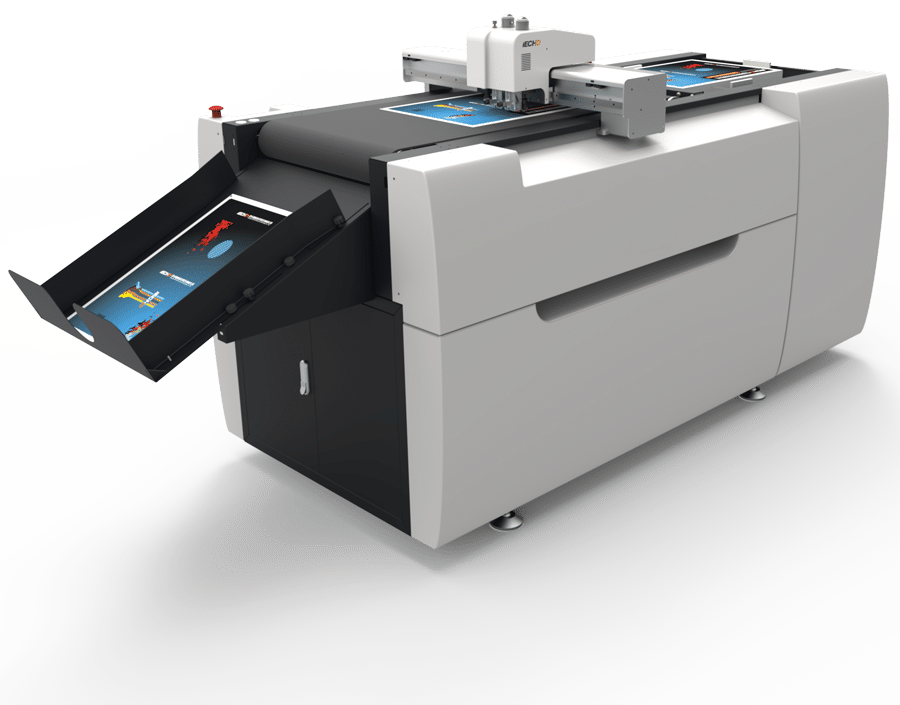

The iECHO PK system is the all-rounder for digital finishing - for the production of folders, folding boxes, stickers, creative die-cuts, packaging and much more.

Fast print data creation through simple file template creation in Illustrator or Indesign

Optimal for your individual short runs

iECHO PK offers a multitude of creative possibilities in the

Comparison with normal cutting and punching systems

low pre-production runs and sample production in final pro-

quality on a wide range of different materials

up to 6 mm possible

Low space requirement

230 V Plug & Play - no infrastructural adjustments are necessary

Tool head

The tool head can hold up to 4 tools* simultaneously. This enables various processing steps such as cutting through, kisscutting, creasing, perforating and marking.

Fully automatic suction feeder

The positioning of the arch is done

fully automatically with the aid of a CCD

Camera. Sheets up to 12 cm stack height can be processed.

High processing speed

Up to 1,000 mm / sec, depending on material

Large variety of materials

Cardboard, grey board, corrugated board, honeycomb board, PP cardboard, PVC, EVA, EPE, rubber, etc.

Up to format B2 and 6 mm material thickness

Simple template creation

Common file formats PDF, EPS, AI and DXF can be processed.

Extensibility

An additional unwinding device for roll material and a touch monitor with integrated computer are optionally available.

Perforation and creasing

Different perforation and creasing tools as well as passepartout cutting option

(V-Cut) available

* Plus version with 4 tools incl. oscillating knife for material up to 6 or 10 mm thick.

KT Board

PP paper

Foam

Plastic

Corrugated board

Grey board

Sticker / Vinyl

Reflective material

Cardboard

Corrugated plastic

ABS board

Magnetic sticker

The main difference between the iECHO models is the size of the cutting table and the maximum sheet thickness.

Menu

Menu