Data check with automatic preflight

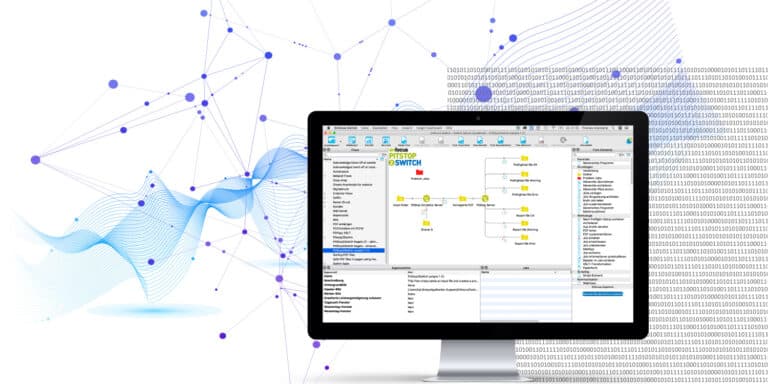

Data verification with automatic preflight. With PitStop to Switch you can automatically check and optimise your delivered customer data. The Steuber service team will help you with implementation and training on the new software.